Did you know?

Who wore the first eyeglasses? In 1268, Italian scientists took natural crystals and created crude, heavyweight, hand held spectacles. The inability to make crystals uniform made for a blurry experience. Glass lenses were lighter, but tended to bend light at different angles causing a rainbow effect. By 1730 Chester More Hall solved the problem by putting two different pieces of glass together to create the achromatic lens. Today's ophthalmic lens processes are so precise thanks to advancements aided by creative minds and sound engineering practices by CMT and other partner companies.

Customer's Challenge

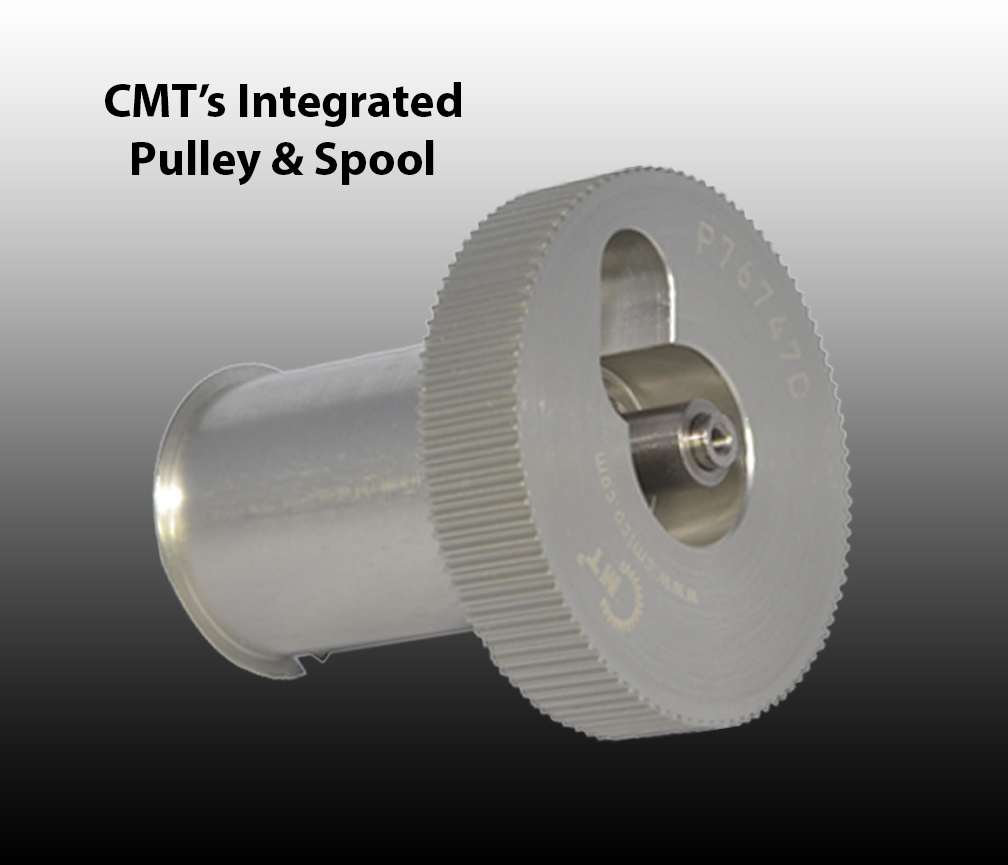

Gerber Scientific, a manufacturer of ophthalmic lens processing equipment, was working with a unique cable spool and pulley assembly consisting of eleven separate components and unreliable fasteners that caused the pulley to separate from the spool and lose registration during operation.

CMT's Solution

Custom Machine and Tool Company's engineering team redesigned the component, eliminating the fasteners and integrating the pulley and spool as a single component. The new design was substantially more cost effective and provided perfect registration during operation.

Need a solution for your challenge? Contact us at: info@cmtco.com.