Did you know?

Prior to 1439, German businessman, Johannes Gutenberg wanted to start printing books on a massive scale. So he rolled up his sleeves, did extensive experimentation and finally created the worlds first printing press.

Laser printing became available in 1969, with dot matrix coming into its own the following year.

The first digital press appeared in 1993. This meant you could now reproduce digital images on virtually any surface; paper, film, cloth, vinyl, plastics, metals even magnets.

Customer's Challenge

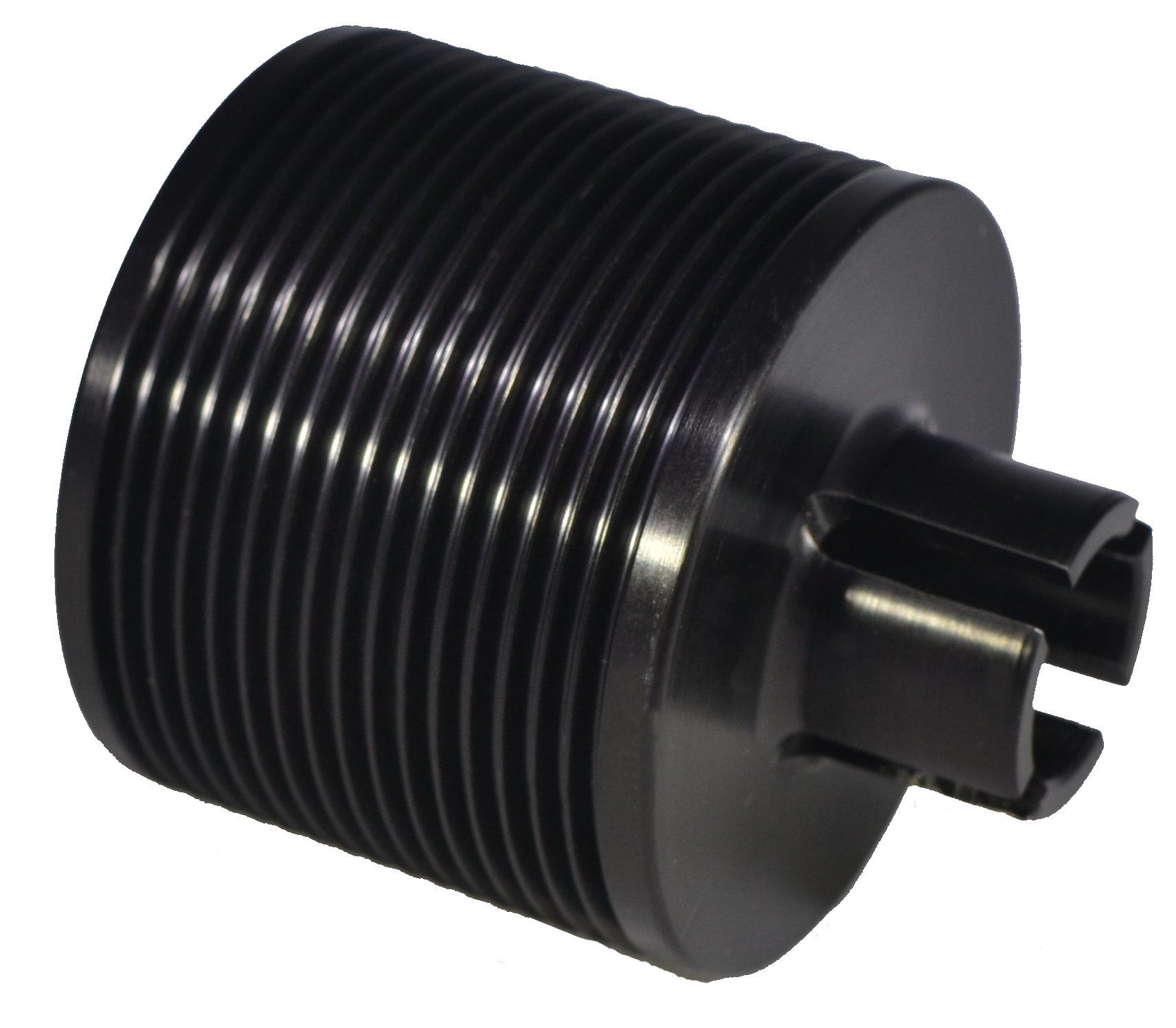

Presstek, a manufacturer of digital printing equipment, was looking for an improvement in the design of a drive pulley used in one of their Laser Imaging machines. The pulley attached at the end of a shaft using clamp collars were prone to slipping, causing vibration and runout, resulting in a loss of productivity and increased maintenance costs.

CMT's Solution

By integrating the CMT connection system CMT was able to remove the clamp collars and reduce the over all size and weight of the part. The new component was more cost effective to manufacture, resulted in improved concentricity and increased productivity.

Need a solution for your challenge? Contact us at: info@cmtco.com.