Did you know?

Clinical Chemistry, the interrelationship of chemistry and medicine was first theorized by 1840 when more than 1400 organic compounds were known. From that time right up until 1957, when the first automated instrument was introduced, analysis was painstakingly slow and not always accurate. The widespread utilization of the auto analyzer and subsequent improvements continue to bring breakthroughs to the world of medicine. CMT is a proud contributor to the advancement of automated medical instruments.

Customer's Challenge

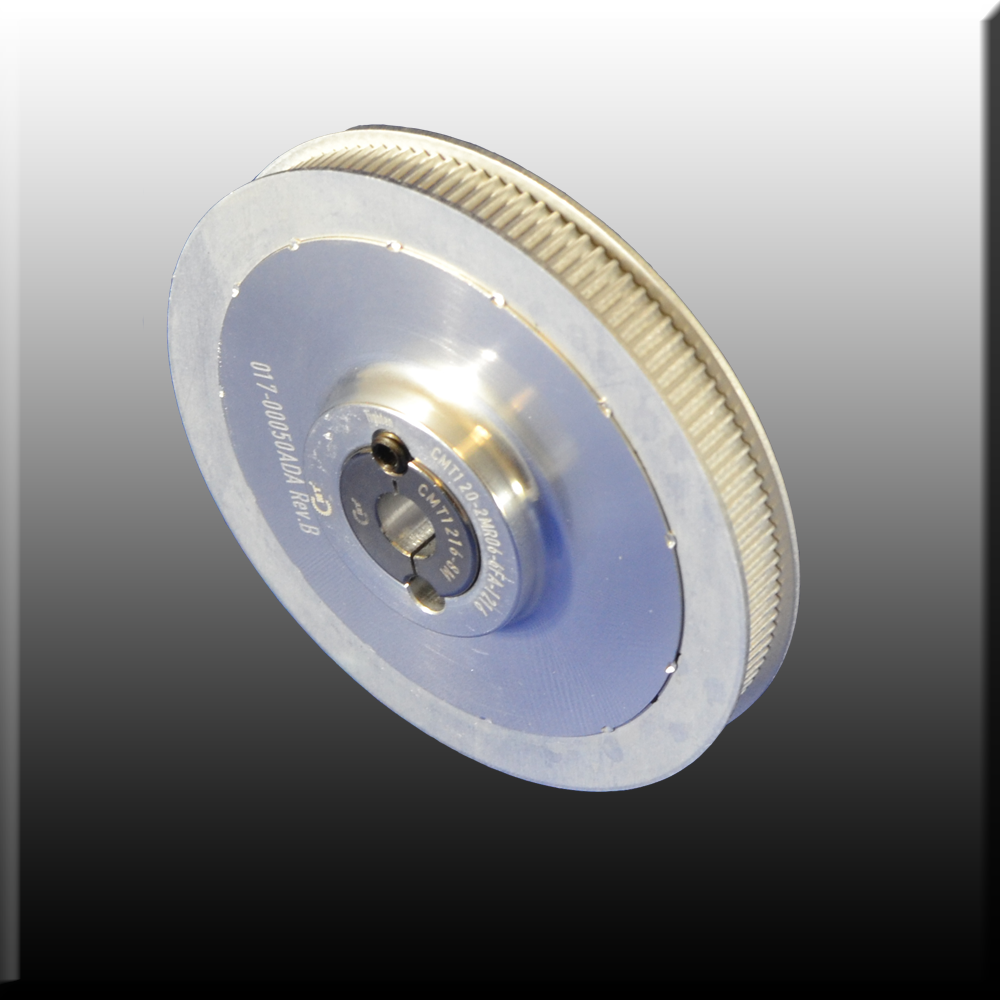

KMC Systems Inc, a designer of precision automated medical instruments, was having trouble with a pulley-to-shaft connection within an automated analyzer. Positional accuracy is extremely important in this application, but loosening set screws and other connection methods proved unreliable, and constant rework and repairs were difficult and costly.

CMT's Solution

After deciding that a better connection system was needed, the designers discovered the Concentric Maxi Torque system. By integrating the Concentric Maxi Torque connection system, they were able to improve concentricity, which in turn, improved positional accuracy. The Concentric Maxi Torque system also eliminated the need for flats on the mating shaft, providing a more cost effective and reliable solution.

Need a solution for your challenge? Contact us at: info@cmtco.com.