Did you know?

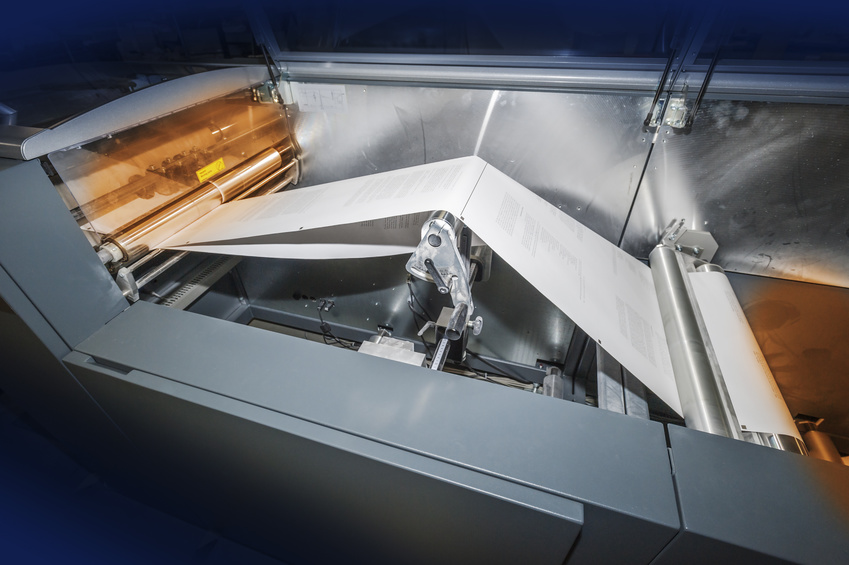

Effective ways of handling paper has been a problem ever since the ancient Greeks started writing on papyrus eons ago. After all, Henry Brown's “receptacle for storing and preserving papers” (the filing cabinet) wasn't invented until 1886. Today, be it in the office, mail room, print shop or factory floor, speed and efficiency are paramount to your success. CMT continues to innovate in partnership with the paper handling industry.

Customer's Challenge

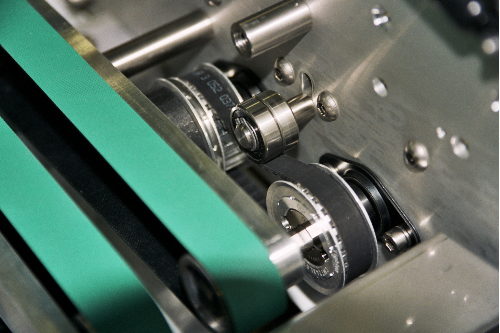

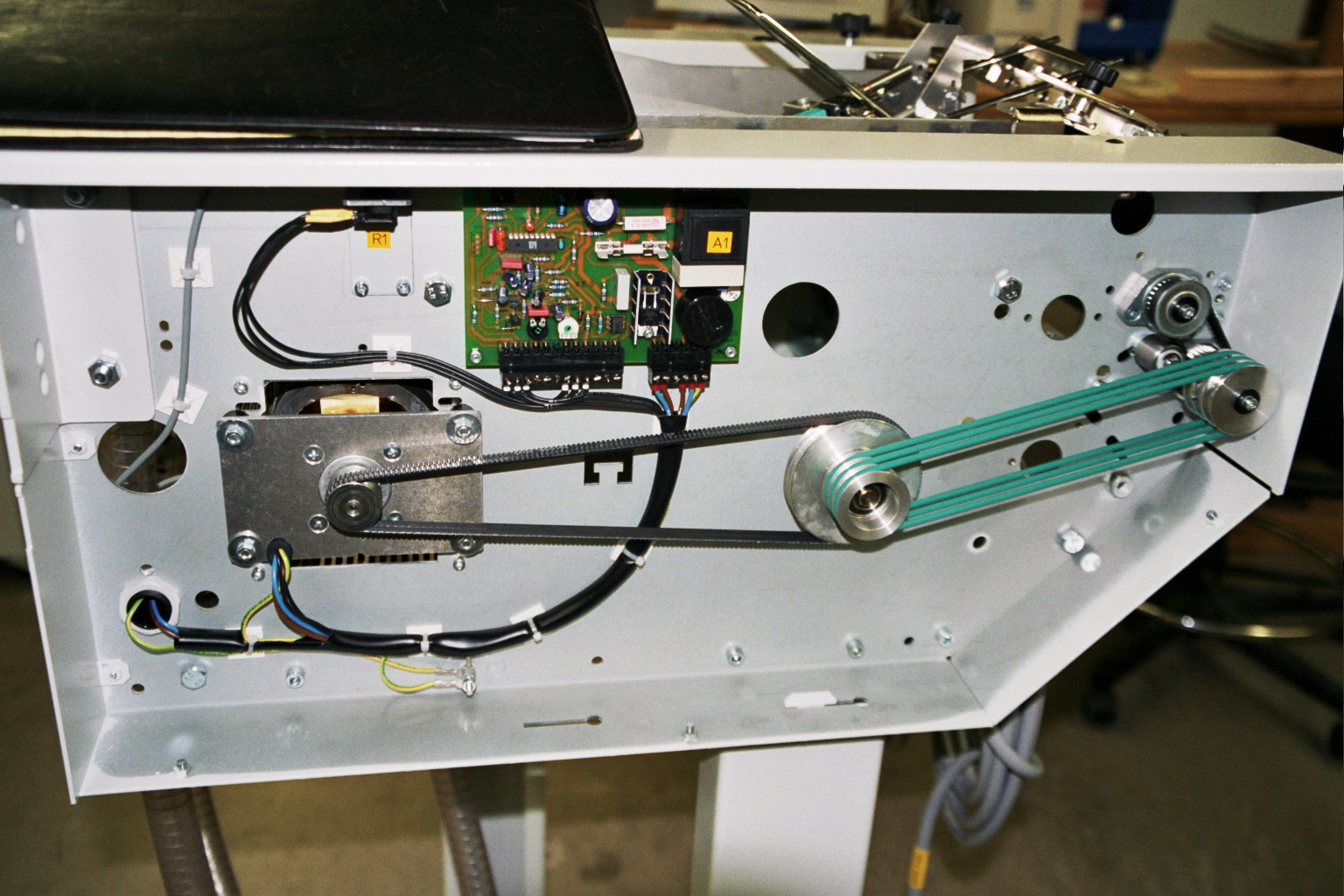

GBR Systems Corporation, a manufacturer of paper handling equipment, was using set screws to connect a high-speed drive pulley, running a Gates Polyflex JB belt, to a 3/8 inch shaft. The set screws would loosen during clutching and braking at high rpm's, causing machine malfunction and belt damage. Constant tightening of the set screws resulted in loss of machine productivity and increased maintenance costs.

CMT's Solution

After investigating the cost of alternative connection methods, GBR turned to CMT and the Concentric Maxi Torque system. GBR concluded that the CMT system provided a positive connection that eliminated the need for secondary machining of the shaft, decreased vibration and reduced runout. Maintenance costs and down time were dramatically reduced due to the benefits of the CMT system.

Need a solution for your challenge? Contact us at: info@cmtco.com.